Home > News

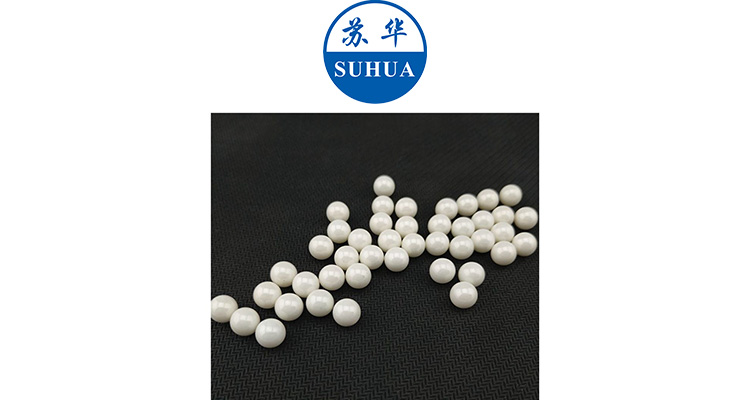

Home > NewsZirconia beads, also known as zirconium oxide beads, have emerged as indispensable components in various industries due to their exceptional properties and versatility. These tiny spheres, often no larger than a few micrometers, possess unique characteristics that make them ideal for a wide range of applications. From biomedical to industrial fields, zirconia beads play a crucial role in enhancing processes, improving products, and advancing research. Let's delve into the diverse applications of these remarkable beads and uncover their significance across different sectors.

In the realm of biomedicine, zirconia beads find extensive use, particularly in dental and orthopedic applications.

Dental Restoration: Zirconia beads are commonly used in dental restorations, such as crowns and bridges. Their biocompatibility, durability, and tooth-like appearance make them an excellent choice for producing aesthetically pleasing and long-lasting dental prosthetics.

Orthopedic Implants: Zirconia beads are also utilized in orthopedic implants, where their biocompatibility and wear resistance are highly valued. These beads are often incorporated into ceramic components of joint replacements, offering patients a durable and biologically inert solution for bone repair and replacement.

Zirconia beads play a pivotal role in catalysis and various chemical processes, owing to their high surface area, stability, and unique surface properties.

Catalyst Supports: Zirconia beads serve as effective catalyst supports in heterogeneous catalysis. Their high surface area allows for greater catalyst dispersion, resulting in enhanced catalytic activity and selectivity in chemical reactions.

Adsorbents: Zirconia beads are utilized as adsorbents for gas and liquid purification processes. Their porous structure and affinity for certain molecules make them suitable for applications such as water purification, gas separation, and removal of contaminants from industrial effluents.

In manufacturing and material processing industries, zirconia beads are extensively employed for grinding and milling various materials due to their high density and wear resistance.

Grinding Media: Zirconia beads are used as grinding media in ball mills and attritors for the comminution of materials such as minerals, pigments, and ceramics. Their high density and superior wear resistance ensure efficient grinding and prolonged service life, making them preferred over other grinding media options.

Milling Applications: Zirconia beads are also utilized in milling applications for the dispersion and homogenization of suspensions and slurries. Whether in the production of paints, inks, or pharmaceutical formulations, zirconia beads facilitate particle size reduction and uniform mixing, resulting in high-quality end products.

Zirconia beads find niche applications in the electronics and optics industries, where precision and reliability are paramount.

Dielectric Materials: Zirconia beads are used as dielectric materials in electronic components such as capacitors and sensors. Their excellent electrical insulation properties and stability at high temperatures make them suitable for applications requiring reliable performance in harsh environments.

Optical Components: Zirconia beads are employed in optical coatings and components due to their high refractive index and transparency in the visible and infrared spectral ranges. These beads contribute to the fabrication of lenses, windows, and laser components used in various optical systems and devices.

In conclusion, the versatility of zirconia beads spans across multiple industries, where their unique combination of properties fulfills diverse functional requirements. From biomedical implants to catalytic applications, from grinding media to electronic components, zirconia beads continue to play a vital role in advancing technology, improving processes, and enhancing products. As research and innovation progress, the applications of zirconia beads are likely to expand further, cementing their status as indispensable materials in modern engineering and science.

View More(Total0)Comment Lists