Home > News

Home > NewsWhen you're picking the right material for steel balls in high-load bearings, it's super important to find a good mix of strength, durability, and performance. Bearings are key players in keeping machines running smoothly—whether it’s heavy industrial gear or car parts—and what you choose for those steel balls can really affect how long they last and how well they work. So, how do you figure out which steel ball material is best for these tough jobs?

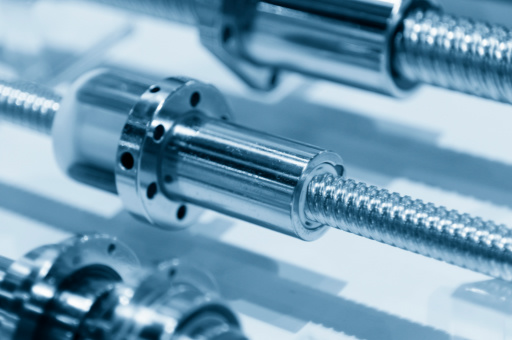

High-load bearings are designed to withstand substantial forces while maintaining smooth operation. These bearings are used in machinery that experiences heavy weights or harsh working conditions, such as in automotive, aerospace, construction, and industrial sectors. For such applications, the steel balls inside the bearings need to be made from materials that can endure both high pressure and extreme stress.

When selecting a steel ball material, consider the following attributes:

Hardness: Harder materials resist wear and deformation under heavy loads, which is essential for high-load bearings. Hardness is typically measured on the Rockwell scale.

Strength: Steel balls need to maintain their structural integrity under intense pressure. The material should have high tensile strength and the ability to resist yielding or cracking.

Corrosion Resistance: High-load bearings often operate in environments that may expose them to moisture, chemicals, or high temperatures. Choosing a material with good corrosion resistance will increase the longevity of the bearing.

Fatigue Resistance: Bearings undergo repeated load cycles, which can lead to fatigue failure. Steel ball materials must be fatigue-resistant to prevent premature failure.

Chrome Steel (AISI 52100): This is one of the most common materials used for steel balls in bearings. It is highly durable, with excellent hardness and wear resistance, making it ideal for high-load applications. Chrome steel’s high-carbon content contributes to its hardness, while its low alloy composition ensures a good balance between strength and flexibility.

Stainless Steel (AISI 440C): For applications requiring corrosion resistance, stainless steel balls like AISI 440C are an excellent choice. These balls provide good hardness, wear resistance, and excellent performance in corrosive environments. Stainless steel is often chosen for industries like food processing, pharmaceuticals, and marine applications.

Ceramic-Coated Steel: Some high-load bearing applications require an extra layer of protection. Ceramic-coated steel balls combine the benefits of both steel and ceramic materials. The ceramic coating provides enhanced wear and corrosion resistance, while the steel core offers superior strength.

Carburized Steel: Carburizing is a heat treatment process that increases the hardness of the outer surface of the steel while maintaining a tough core. This material is ideal for applications where high surface hardness and resistance to rolling contact fatigue are essential.

Hybrid Bearings (Steel Balls with Ceramic Rings): Hybrid bearings are designed for even more extreme conditions. These bearings combine ceramic balls with steel rings. The ceramic balls provide low friction and wear resistance, while the steel rings offer superior strength. Hybrid bearings can withstand higher speeds and loads than traditional steel ball bearings.

The right choice of steel ball material will depend on several factors, including:

Load requirements: Determine the maximum load the bearing will be subjected to and choose a material with sufficient strength and fatigue resistance to handle these loads.

Environmental conditions: Consider exposure to moisture, chemicals, or high temperatures. If corrosion is a concern, stainless steel or ceramic-coated steel may be necessary.

Speed of operation: Bearings operating at high speeds may require materials with low friction properties, such as ceramic or hybrid bearings.

Durability and cost: While materials like ceramic offer excellent performance, they are often more expensive. Balance cost with the expected performance and longevity of the bearing.

Choosing the right steel ball material for high-load bearings is crucial for ensuring reliable and long-lasting performance. The ideal material will depend on the specific demands of your application, including load-bearing capacity, environmental factors, and speed requirements. By understanding the various material options and their properties, you can make an informed decision that will optimize your bearing's performance and extend its service life. So, which steel ball material will you choose for your high-load bearing needs?

View More(Total0)Comment Lists